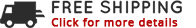

3M™ Roto Peen Flap Assembly, 1 in x 2 in TC 330, 5 per case

-1

SKU: 7000000787

3M™ Roto Peen Flap Assembly, 1 in x 2 in TC 330, 5 per case

SKU: 7000000787

$149.88

/ Each

Add $199.00 worth of items to your cart to qualify for

Minimum Order Quantity: 5 Each

QTY:

SHIPPING DIMENSIONS

Height: 4.70 Inches

Width: 4.70 Inches

Length: 6.40 Inches

Weight: 0 Lb(s) 3 Oz

Technical Specifications

- Imparts a compressive residual stress that benefits the material by strengthening its durability

- Flap/mandrel assembly is portable for added convenience

- Tungsten carbide shot is bonded to the flaps, providing a cleaner peening method than loose shot "blasting"

- Available in three flap sizes for both small and large surface areas

- Especially effective for precision in-service rework, manufacturing, repair of small areas, and peening holes

Peen surface with a circular motion. Tool must be pre-set to a constant torque

Flap/mandrel assemblies are especially effective for precision in-service rework, manufacturing, repair of small areas and peening holes. The 3M™ Roto Peen Flap Assembly comes in three sizes and allows for peening a variety of surfaces and radii area. Plus, the uniform TC-330 shot size contributes to consistent results. As the part is peened, a compressive residual stress is created. It's a non-yielding layer that increases the material's ability to fight fatigue, stress and fracturing.

Flap rotation speed is the most important factor affecting peening intensity. Increasing the speed of rotation increases the intensity. Conversely, decreasing the speed decreases the intensity. To ensure uniform peening coverage, operators should use a circular or oscillating motion over the entire area.