3M™ Trizact™ Finesse-it™ Film Disc Roll 466LA, 2 in x NH, A5 grit, 500 discs per roll, 4 rolls per case

-1

SKU: 7000118304

3M™ Trizact™ Finesse-it™ Film Disc Roll 466LA, 2 in x NH, A5 grit, 500 discs per roll, 4 rolls per case

SKU: 7000118304

$611.73

/ Roll

Adding this item to your cart will qualify your order for

Minimum Order Quantity: 4 Roll

QTY:

SHIPPING DIMENSIONS

Height: 5.81 Inches

Width: 12.00 Inches

Length: 12.00 Inches

Weight: 6 Lb(s) 0 Oz

Technical Specifications

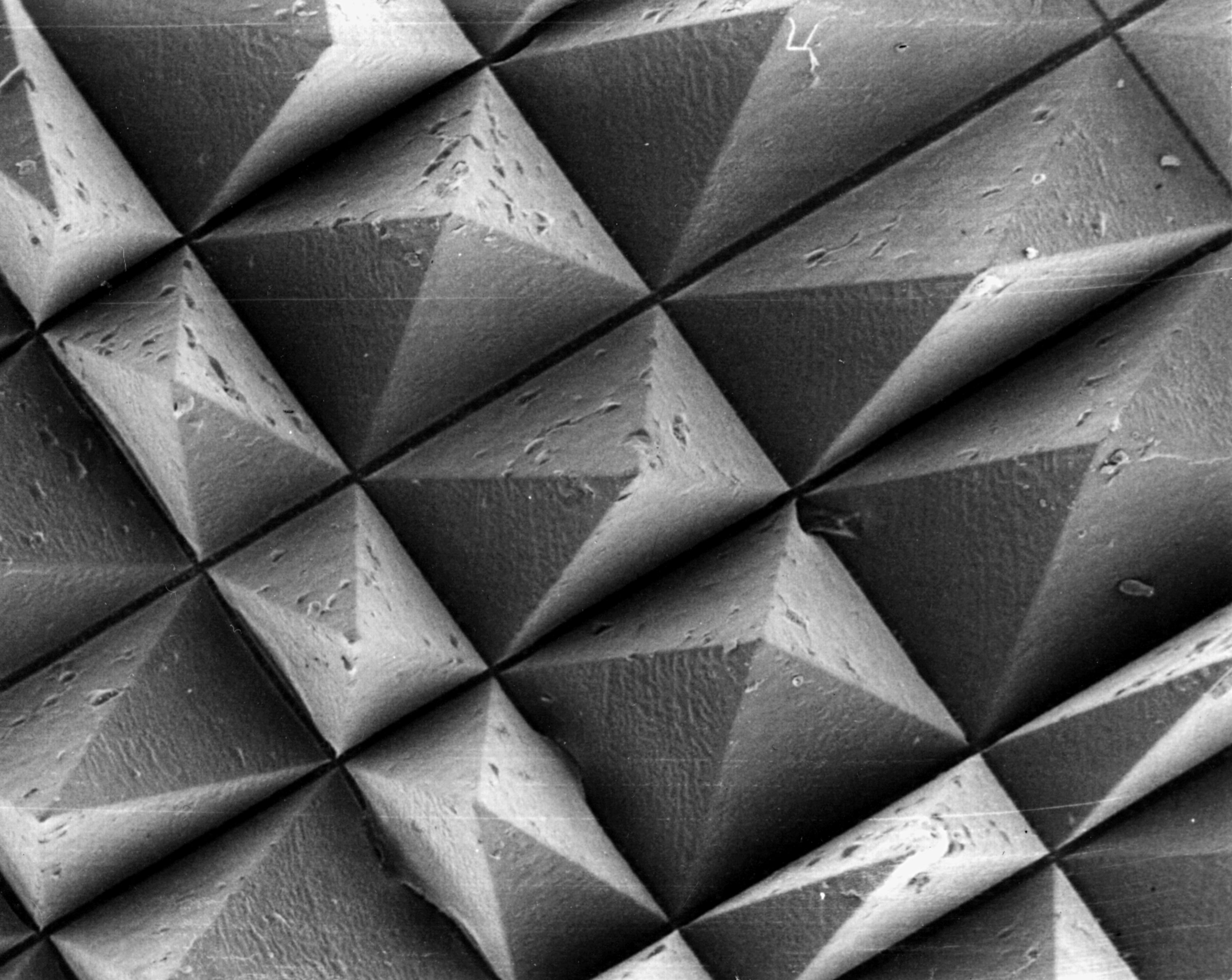

- 3M™ Trizact™ abrasives start sharp and stay sharp, resulting in more predictable finishes and improved, consistent results

- Ideal for the 3M two-step paint defect repair process for automotive finishes

- Well suited for use on mini random orbital sanders to produce a polish-ready finish

- Silicon carbide mineral in three very fine micron grades

Trizact™ Abrasives remove defects, leaving a consistent finish that is easy to polish out

- Level/remove the defect using the 3M™ Elite Series Mini Orbital Sander 28737 or the 3M™ Mini Random Orbital Nib Sander 20244 and a 3M™ Trizact™ Finesse-it™ 466LA disc

- Spray the disc with water to prevent the abrasive from loading during sanding

- Sand the defect for 1 to 3 seconds, depending on its size

- Wipe the area clean with a Scotch-Brite™ High Performance Cloth

- Level/remove the defect using a 3M™ Finesse-it™ Hand Pad and a 466LA disc

- Spray the 466LA disc with water to prevent the abrasive from loading during sanding

- Sand the defect for 3 to 5 seconds, depending on its size

- Wipe the area clean with a Scotch-Brite™ High Performance Cloth

3M™ Trizact™ Abrasive surface, 50x magnification